We all know that converting from Metal Halide (High Intensity Discharge) to LED Light will save much more energy as well as money.But how much energy does a LED light saves compared with traditional lights? The most asked question is: How many watts LED high bay bulb can replace my current Metal halide lamp 400w and 250w?

In this post, we analyze top 5 factors why you should convert from Metal Halide to LED.

1. Lamp (Source) Efficiency Vs Fixture (System) Efficiency

Typical 400 watt metal halide bulb has 36000 initial lumens and 20,000 life hours. So while 36,000 lumens sounds impressive, within 6 months, it can be below 30,000 lumens, losing almost 20% of lumens. Lumen depreciation in a metal halide bulb is relatively quick. It is noted that around 8,000-10,000 hours, lumen depreciation is already at 50%.

A Metal Halide bulb is omni-directional. That means light is distributed in every direction. So it produces as much light horizontally parallel to the ground as it does facing downwards.

In fixture design, you add a reflector to do gather, collect and deliver the light. The main problem with reflected light is how effective is the reflector getting the light that bounces off of it to the ground. A lumen that bounces off the reflector and bounces back into the fixture is considered a loss lumen. As much as 30% or greater of the light can be lost in this reflective bounce. So if we do the math of a metal halide bulb in a high bay fixture, after 6 months we would expect the fixture effective lumen efficiency to be:

36,000 lumens – 20% (initial lumen loss) = 28,800 lumens

Lumens loss from reflector bounce: 8,640

Total lumens after 6 months in High Bay fixture: 20,160

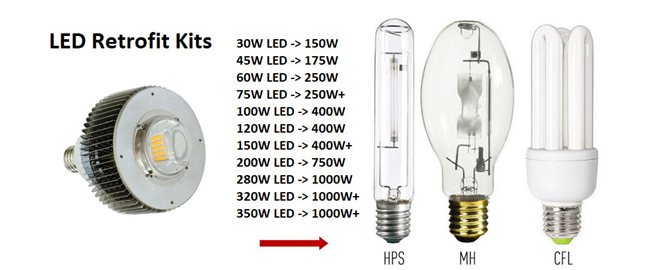

Compare this to LED in which all the light is directional, in that, it is directed to where it is needed. Reflectors are not required. In terms of lumen depreciation, LED takes a lot longer to happen. For example, our LED retrofit kits have a L70 (lumen depreciation to 70% of initial lumens) of over 100,000 hours.

2. Operating Life

As mentioned, the operating life of a typical Metal Halide bulb seems to be around 20,000 hours. Larger bulbs, like a 1000 watt Metal Halide, are around 15,000 hours. In terms of LED, there are different ways suppliers describe the life of the product. One way is to mention L70. L70 is not a measurement of end of life, but it is a measurement of lumen degradation up to 70% of initial lumens. This does not mean the driver or ballast or some other component might fail prematurely.

What we do know is the life of a Metal Halide bulb is around 15,000 to 20,000 hours. What we also know is that at half life, it has already lost 50% of its initial lumens. So while not dead, highly ineffective. For the record, it still consumes 400+ watts even though it is half as bright.

Compare that to our LED Retrofit Kit rated at 100,000 hours (L70). So by the time the LED head reaches 100,000 hours, you have done 5 Metal Halide bulb replacements, possibly more.

3. Efficiency (lumens/watt)

The more efficient the bulb is, the more money you will save. So let’s calculate the lumen efficiency of metal halide versus LED.

To calculate lumen efficiency, you need to take the total lumens produced and divide it by the total watts consumed. In the case of Metal Halide, you also have to include ballast draw. If you recorded the total watts consumed of a typical 400W bulb, it is around 455 watts. The ballast consumes about 15% more energy over and above the bulb consumption.

So calculating lumen efficiency for metal halide: 36,000 lumens / 455 watts = 79.12 lumens/watt.

Let’s compare that with our 150 watt LED Retrofit Kit: 23,250 lumens / 150 watts = 155 lumens/watt. Almost double of Metal Halide.

4. Energy Savings

So in the above discussion, something important was pointed out. Above we talked about the mean lumens of a 400W Metal Halide to be around 20,500 lumens. Our 150W retrofit kit produces 23,250 lumens, but instead of burning 455 watts, it consumes only 150 watts. That represents a 66% savings in energy consumed to produce more light.

5. Savings on Maintenance

We have just as many customers wanting to convert to LED because of maintenance savings as they do for energy savings. Think about what we discussed, over the life of the LED retrofit kit, a customer would have to do 5-6 Metal Halide replacements. The higher the installation height, the higher the cost of replacement. And if you have a facility loaded with lights, this becomes a significant budget amount every year that you must take into consideration.